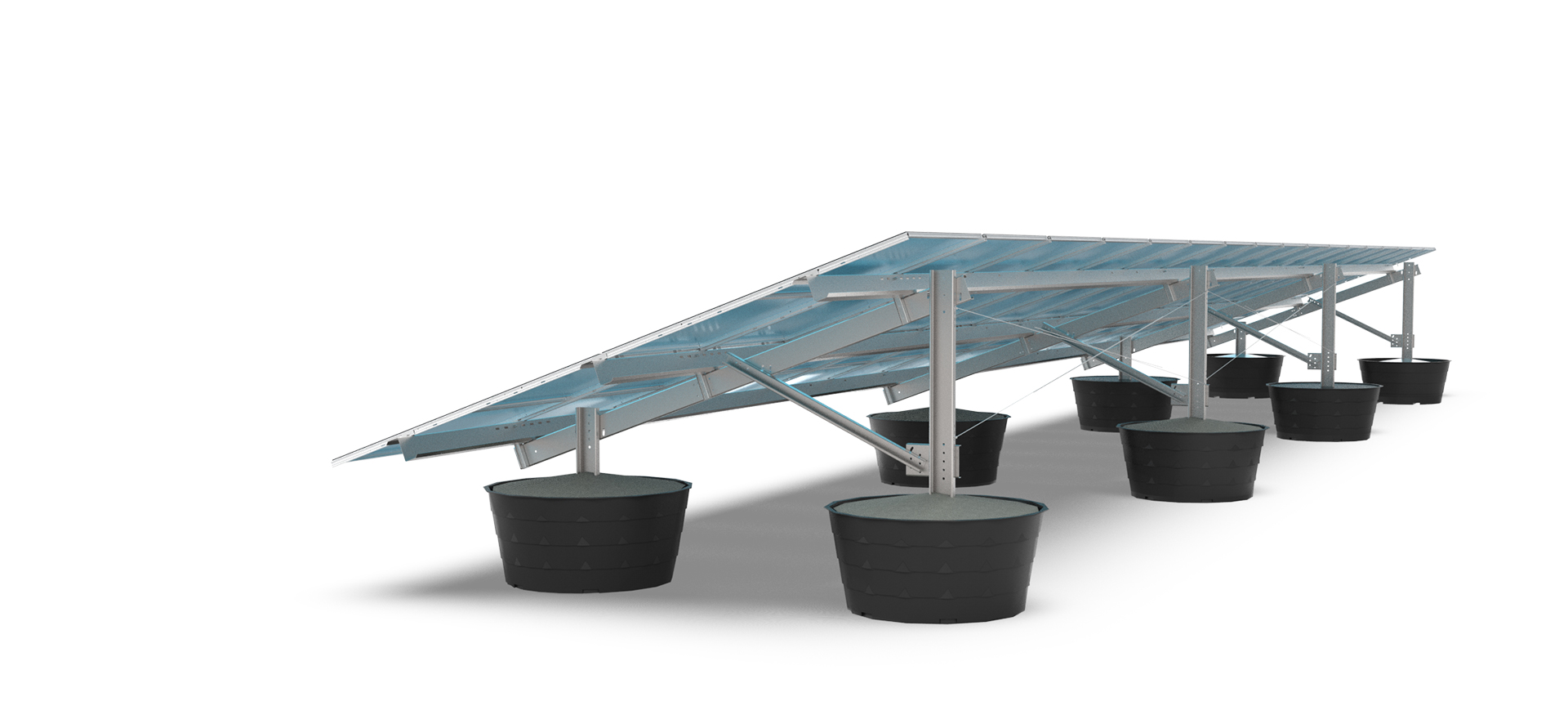

The TITAN Pour-N-Go foundation is ideal for landfill and brownfield sites where the ground cannot be penetrated. The Pour-N-Go buckets are made from rigid, high-strength plastic material with an engineered foundation and rebar. They are easily transported, staged, and allow for the racking to be completely built prior to filling with concrete. Two buckets per foundation set allows for flexibility on sites with topography.

Spec SheetTITAN Pour-N-Go

- Ideal for landfill and brownfield sites.

- Rigid, high-strength plastic material with an engineered foundation and rebar.

- Two buckets per foundation set allows for in-field flexibility.

- Easily transported, staged, and allows for racking to be build prior to filling with concrete.

Standard Specifications

Engineering: ASCE 7-10/ 7-16/ CPP Wind Tunnel Tested

Grounding: Fully Integrated UL2703

Foundation: Pour-N-Go Ballast

Tilt Angles: 5°-35° Options

Racking Coating: Galvanized; G90

Wind Loading: Up to 165mph

Snow Loading: Up to 100psf

Mounting Orientation: 2-High Portrait

Warranty: 25 Years

Documents

Pour-N-Go Buckets

Eliminate hefty transportation costs of precast concrete with the TITAN Pour-N-Go. The Pour-N-Go buckets are made from rigid, high-strength plastic material with an engineered foundation and rebar. Using two buckets per foundation set allows for flexibility on sites with topography. Integrating the TITAN racking with our Pour-N-Go system provides the most durable racking with the longest spans for sites where the ground is impenetrable.

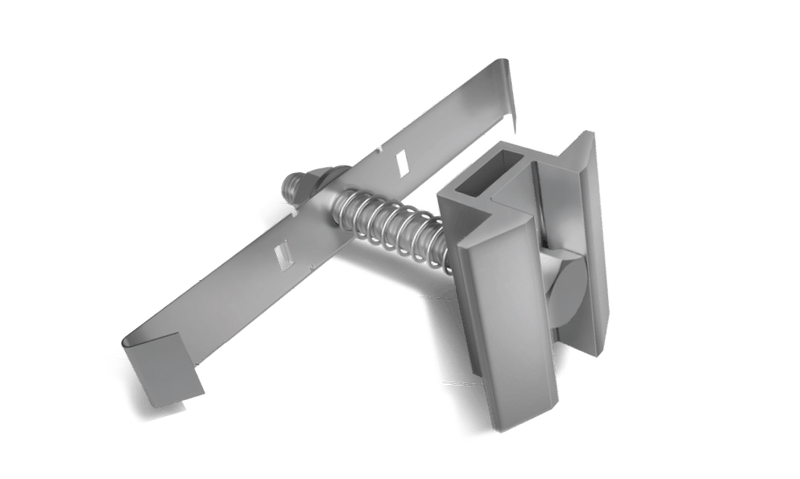

Gravity Clip

The gravity clip assembly has fully integrated module grounding, built in hooks that allow for rapid module installation, accommodates different module widths and provides positive locking to ensure the clamp won’t loosen over time due to ice or vibrations.